NRF is a manufacturer a wide variety of aluminum cooling parts. All produced in our own European production facilities. NRF’s aluminum coolers are known for the high quality and durability. Because we manufacture all coolers by ourselves, we can a wide variety of sizes and multiple fin systems.

Our cores are manufactured by using aluminium alloys such as series 3XXX, which provides a great performance in terms of:

5XXX and 6XXX alloys are mainly used either formed and extruded in other components such as brackets, tubes, frames, and tanks.

Soldering or brazing?

Soldering makes a joint between base metals by melting only filler material, which wets base metal surface because of capillary action. The solder melts at a temperature below 450°C

The heating sources such as torch, furnace, and induction coil are used in different steps of our process to achieve the best result in each component as well as the composition of the filler material.

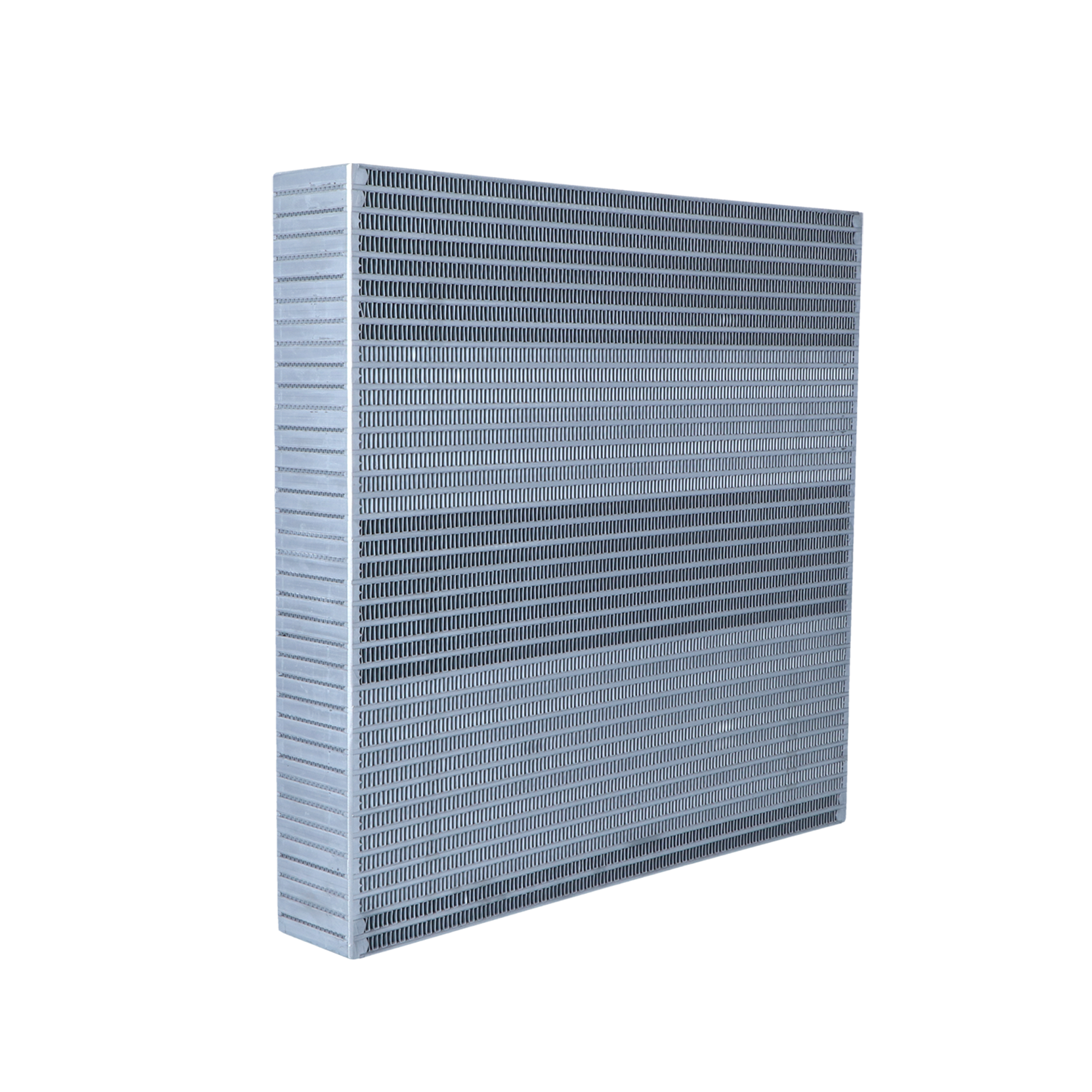

Offset fins

In general terms offset fins increase the heat exchangers performance, increasing the surface contact (air/water side) and making the coolers more compact. NRF has develop a different range of offset fins to be able to achieve the better performance taking in account the pressure drop from this fin.

Hemmed fins

Hemmed fins can be used to reinforce the fin. If your vehicle will experience an intensive use and will need to be cleaned periodically then we recommend this fin to withstand the test of time.

Larger fin

A larger fin pitch helps make the cleaning process faster and more effective. For example, for agriculture uses a lot of debris is trapped in the radiator which can cause a malfunction in the vehicle due to overheating. The Agrifin (which has a larger fin pitch) is perfect for an easy cleaning with a high-pressure washer.

Application: heavy duty materials, construction, agriculture vehicles, rail, gensets, special requirements.